Our Credibility

What we've done so far

The "guts"

The "guts"

Part 2

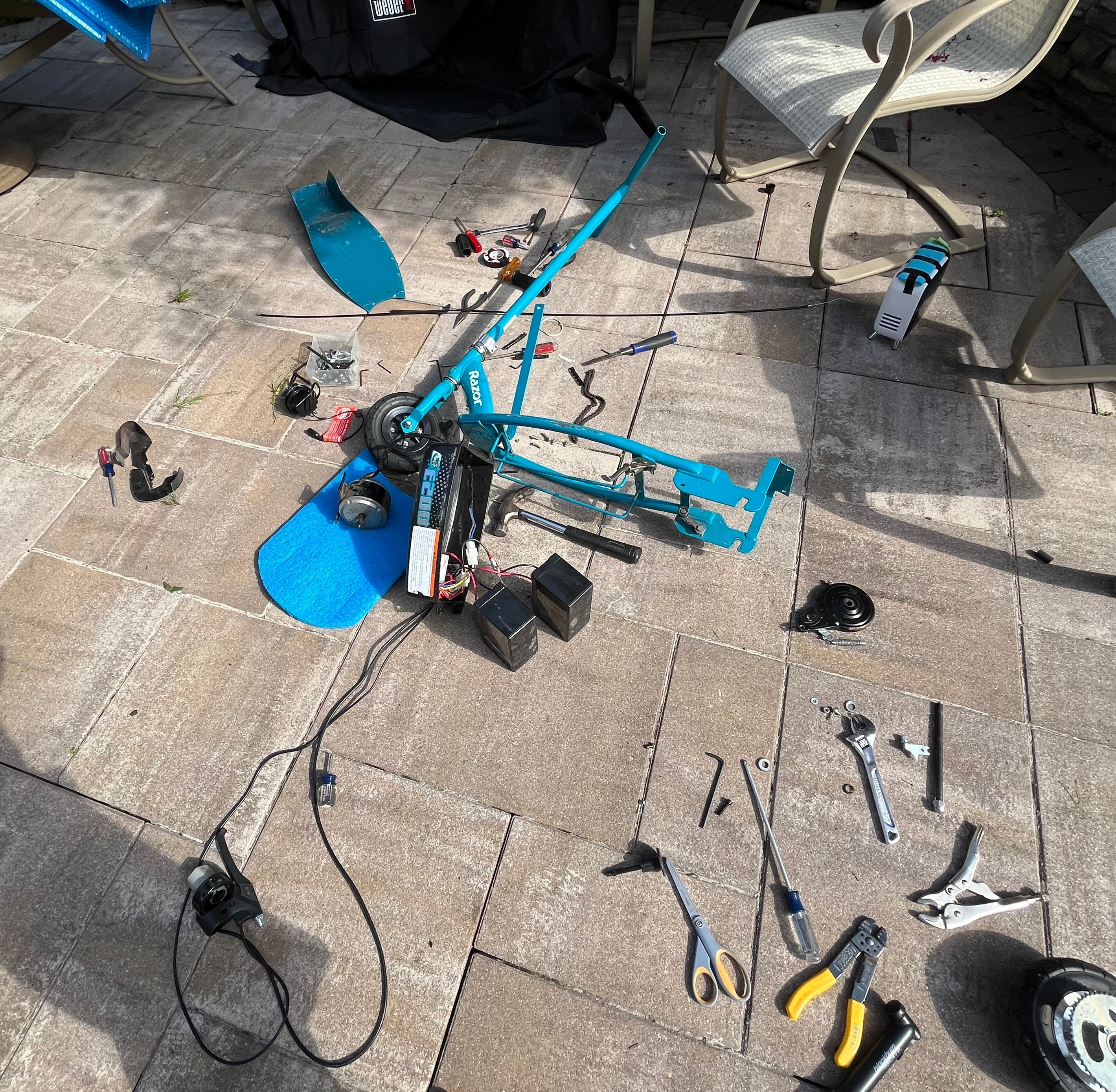

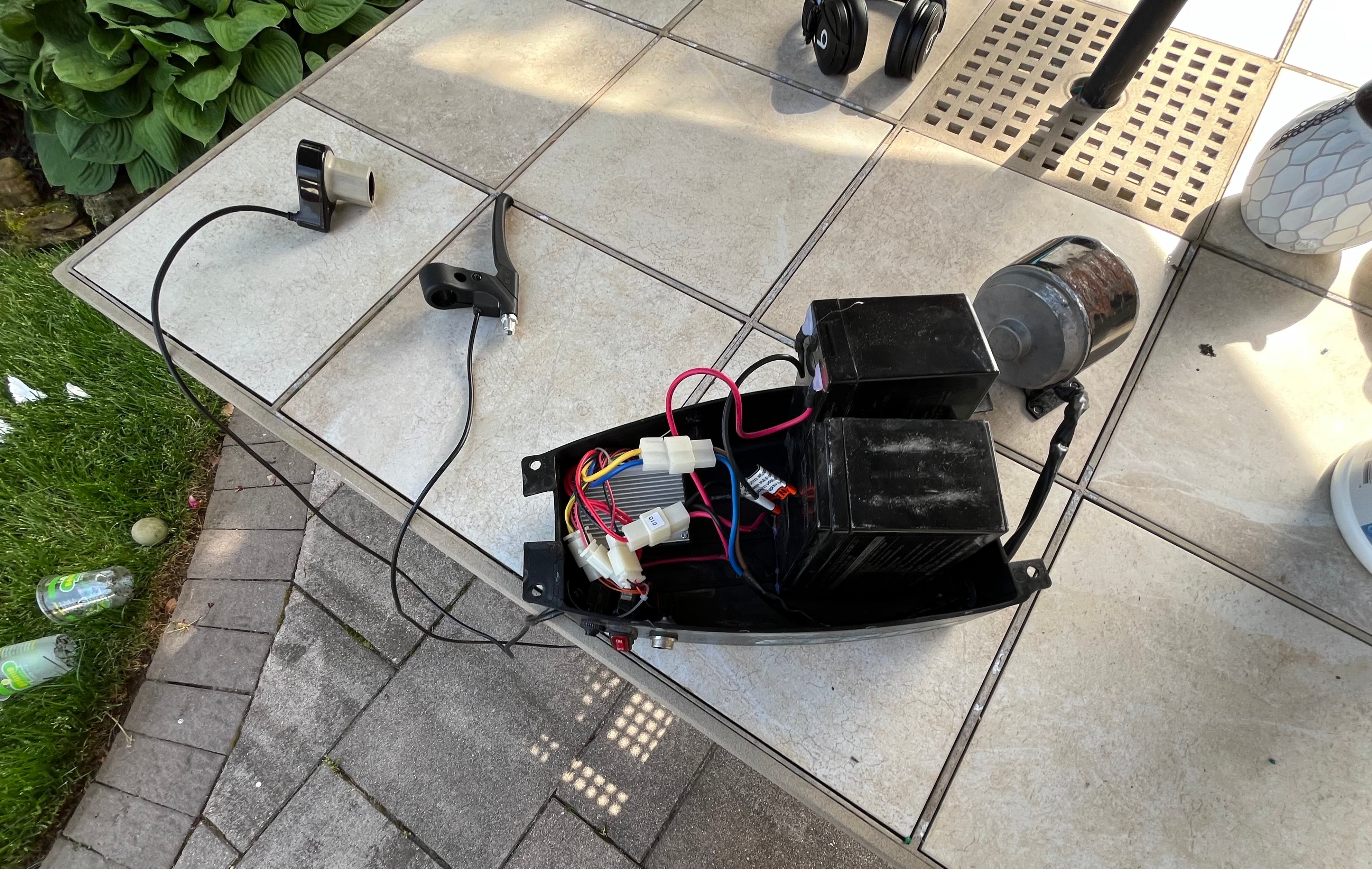

From that Razer scooter, these are the parts Evan extracted: motor controller, motor, 2 batteries, power switch, charging port, reset button, throttle, and motor-kill throttle. The lead-acid batteries were 10 years old and no longer provided enough voltage to move the motor. Evan then bought 2 new 12v 7ah batteries to replace these.

Wheel modification

Wheel modification

Part 3

The next step was installing these parts on a bike. To make the bike a hybrid, we installed a sprocket on the opposite side of the wheel with the original cassette. This way, when the motor runs, the wheel can ratchet and the pedals won't move. We had to remove the wheel and disassemble it multiple times- the first because the tire tubing exploded. We eventually got the hang of it. Justin shined in this part.

Motor mounting

Motor mounting

Part 4

Mounting the motor was a difficult task. First, we thought we could use metal wire and "sew" it on tight. Didn't even come close to working. Being limited on what we had, we decided to use... tape. Yeah, tape. Surprisingly enough, it actually held! But we knew we couldn't just leave it taped on there. Justin and Evan found some scrap metal laying around and found a way to "clamp" on on the frame of the bike. The tape helped us keep the motor steady, lol. Clamping was a good idea and firmly held the motor in place.

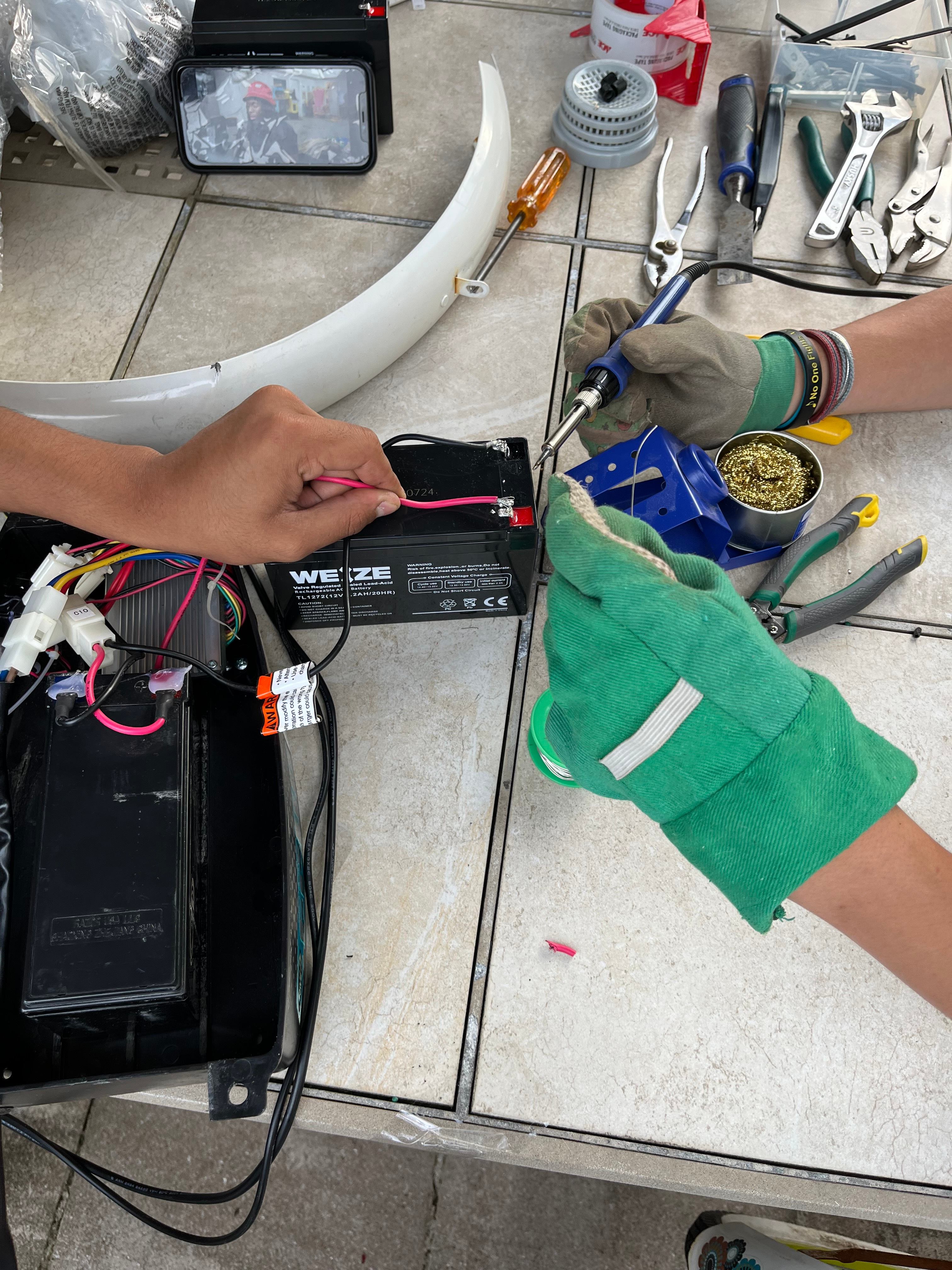

Soldering

Soldering

Part 5

Mason came later and helped us solder the new batteries to the original components. After some frustration because the solder wouldn't stick, he persevered and found a method that worked. Thank god Evan found the soldering station because we tried to use a lighter to melt the original solder. Yeah, no. Didn't work. We cut the ends of the original wires off the terminals, used a wire cutter to expose new metal, and then soldered those newly exposed wires to the contacts of the batteries.

Charging

Charging

Part 6

We charged the batteries for about 10 minutes- granted, the batteries already came charged- and then came the moment of truth. Did it work? We switched it on and turned the throttle.... IT WORKED!!! The motor spun in the right direction, thankfully, and the chain-sprocket subsystem turned the wheel. These invested hours payed off in the end.

Motor Installation

Motor Installation

Part 7

We had to use another bike since the blue one unfortunately had too many issues. Mason graciously donated a spare bike he had on hand so we could continue our efforts. Mason installed a sprocket on the other side of the cassette (accidentally breaking a screw 😬) and then mounted the motor. Along with this, a pair of new handle bar grips that had a throttle were installed.

Motor Installation

Motor Installation

Part 8

Mounting the batteries was a tricky issue. We wanted to center the weight of the bike by placing the batteries within the triangle of the frame, but did not have a good method of doing so. So, Evan proposed that we drill a big box onto the back mount to store them instead. The width of the box was quite a lot larger than those of the batteries, so we reused a bunch of styrofoam packaging that came with the components to fill the gaps.

Wire Soldering

Wire Soldering

Part 9

Next, we had to connect the batteries. To do this, we needed the 3, 12v batteries to be wired in series to yield 36v in total. Doing so, we needed to cut and solder on metal plugs that slid over the battery terminals. This was a fairly straightforward process but was very time consuming. Each wire had to be measured, cut, stripped, crimped with a thin metal prong, soldered, and then crimped again when inserted into a battery terminal plug.

Connecting

Connecting

Part 10

After the batteries were wired together, we then had to connect them to the motor controller. Now, as you can see from this picture--moments before disaster--the wires weren't insulated at this point. As soon as Evan plugged in the black wire, the metal contacts shorted, causing an arc of plasma to fuse the two together 🤯. Immediately, Mason and Evan panicked and ripped apart one of the battery terminal plugs to disconnect the circuit. Lesson learned! Lol. Right away, we made sure to properly insulate the wires to make sure this doesn't happen again. Once everything was properly connected, the key was able to turn on the bike and the throttle was able to spin the motor. Whoo hoo!

Completion

Completion

Part 10

After a long journey, we finally ended up with a finished product. The bike will soon have a new home and will provide transportation and joy to it's new owner. We're grateful that we were able to have this experience and hope to continue creating ebikes for people in our community.